Hamilton Beach ice cream makers offer a delightful way to create frozen treats at home! These appliances‚ like the 68320 model‚ simplify the process‚

requiring no rock salt and fitting conveniently in your freezer. Enjoy homemade ice cream‚ frozen yogurt‚ and sorbets with ease‚ following simple instructions for a perfect result.

What is a Hamilton Beach Ice Cream Maker?

Hamilton Beach ice cream makers are electric appliances designed for easy‚ at-home frozen dessert creation. Models like the 68320 and 68880 utilize a canister that must be thoroughly chilled – typically for at least 24 hours – before use.

These makers don’t require rock salt; instead‚ they rely on the pre-frozen canister to freeze the ice cream base as a dasher continuously churns it. They are capable of making not just ice cream‚ but also frozen yogurt and sorbet‚ offering versatility for dessert lovers.

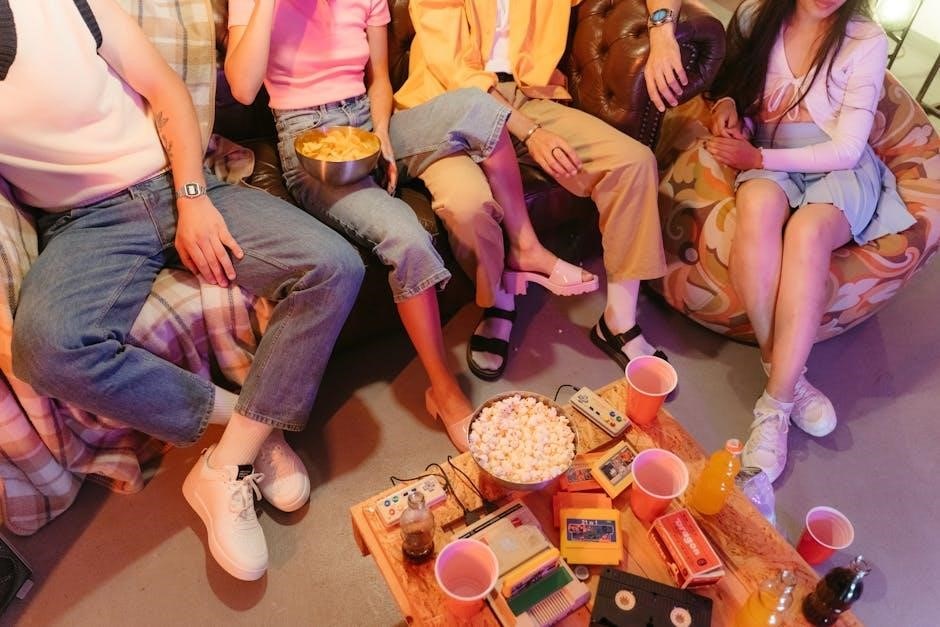

Benefits of Making Homemade Ice Cream

Creating homemade ice cream with a Hamilton Beach maker offers numerous advantages! You have complete control over ingredients‚ avoiding artificial flavors and preservatives found in store-bought brands. Recipes benefit from a full 24-hour chilling period for optimal texture and volume.

It’s a fun‚ creative activity for all ages (though supervision is needed for those under 12). Plus‚ you can customize flavors and mix-ins to your exact preferences‚ exploring frozen yogurt and sorbet variations beyond traditional ice cream. Enjoy fresh‚ delicious results!

Understanding Your Ice Cream Maker Model

Hamilton Beach offers various ice cream maker models‚ such as 68320 and 68880. Familiarizing yourself with your specific model number is key to accessing the correct instructions and support resources.

Identifying Your Specific Model Number (e.g.‚ 68320‚ 68880)

Locating your Hamilton Beach ice cream maker’s model number is the first step towards successful operation and troubleshooting. This number‚ often found on the underside of the unit or within the instruction manual‚ is crucial for accessing specific support materials.

Common models include the 68320 and 68880‚ but variations exist. Knowing your exact model ensures you’re referencing the correct diagrams‚ parts lists‚ and troubleshooting guides. The model number unlocks access to online manuals and assistance from Hamilton Beach directly‚ guaranteeing a smoother ice cream-making experience.

Key Components of the Ice Cream Maker

Understanding the parts of your Hamilton Beach ice cream maker is essential for assembly and operation. Key components include the motor base‚ which powers the churning process‚ and the freezer canister‚ responsible for freezing the mixture.

The dasher‚ inserted into the canister‚ mixes the ingredients as it rotates. A lid secures everything‚ preventing splashes. Proper alignment of these parts is vital. The large ingredient opening simplifies adding mix-ins. Familiarizing yourself with each component ensures efficient and enjoyable ice cream creation.

Preparation Before You Begin

Successful homemade ice cream relies on thorough preparation! Crucially‚ pre-chill the canister for at least 24 hours. Also‚ pre-chill your ice cream base; never shortcut cooling time for optimal results.

Chilling the Canister: Crucial First Step

Proper canister chilling is paramount for successful ice cream making with your Hamilton Beach machine. The freezing process requires a thoroughly cold canister to quickly freeze the ice cream base as it churns. Ensure the canister is placed in the freezer for a minimum of 24 hours before use.

A helpful tip‚ discovered by many users‚ is to allow the frozen canister to sit at room temperature for approximately four minutes after removal from the freezer. This slight warming reduces the formation of frozen walls‚ improving the churning process and final texture.

Pre-Chilling the Ice Cream Base

Preparing your ice cream base ahead of time is strongly recommended for optimal results with your Hamilton Beach ice cream maker. Allowing the mixture to chill completely‚ ideally for at least 24 hours‚ significantly enhances the final product. This extended cooling period allows flavors to meld and the mixture to increase in volume‚ leading to a smoother‚ richer texture.

Never attempt to shorten this crucial cooling time; patience is key! A well-chilled base ensures efficient freezing during the churning process‚ preventing a grainy or icy consistency.

Importance of Cooling Time (At Least 24 Hours)

Adequate cooling time – a minimum of 24 hours – is paramount when using a Hamilton Beach ice cream maker. This extended period isn’t merely a suggestion; it’s a critical step for achieving superior ice cream quality. Allowing the base to chill thoroughly enables full flavor development and proper emulsification of ingredients.

Skipping or shortening this step can result in a grainy texture and diminished taste. The mixture needs ample time to reach a consistently cold temperature for effective churning and freezing.

Assembling the Ice Cream Maker

Proper assembly is key! Attach the dasher and lid securely‚ ensuring correct alignment for optimal churning. Remember the “4-minute rule”: let the canister sit at room temperature before use.

Attaching the Dasher and Lid

Carefully position the dasher into the chilled canister‚ ensuring it fits snugly and can rotate freely. The dasher is the component responsible for churning and creating the ice cream’s smooth texture. Next‚ securely attach the lid to the canister; a proper lock is essential to prevent overflow during operation.

Double-check that the lid is firmly in place before powering on the unit. Ensure proper alignment between the lid‚ dasher‚ and canister to guarantee efficient churning and prevent any mechanical issues. A misaligned setup can lead to uneven freezing or a stalled motor.

Ensuring Proper Alignment

Correct alignment is critical for optimal performance of your Hamilton Beach ice cream maker. Verify the dasher is centered within the canister and rotates without resistance. The lid must lock securely onto the canister‚ creating a tight seal to prevent overflow during the churning process.

A misaligned dasher or lid can cause the unit to malfunction‚ resulting in uneven freezing or a stalled motor. Pay close attention during assembly‚ and double-check all connections before powering on. Proper alignment guarantees efficient churning and a consistently smooth ice cream texture.

The 4-Minute Rule: Canister Temperature

A crucial step for successful ice cream making with your Hamilton Beach machine is adhering to the “4-Minute Rule.” After removing the frozen canister from the freezer‚ allow it to sit at room temperature for precisely four minutes – use a timer! This brief warming period minimizes the formation of frozen walls;

This prevents strain on the motor and ensures even freezing. Ignoring this step can lead to a jammed unit or poorly textured ice cream. The slight thaw allows for smoother churning and a creamier final product‚ maximizing your Hamilton Beach experience.

Making Your Ice Cream Mixture

Delicious ice cream begins with a well-prepared mixture! Explore recommended recipes‚ but always ensure your recipe doesn’t exceed the fill line to prevent overflow during churning.

Recommended Recipes

Hamilton Beach doesn’t limit you to just traditional ice cream! Explore a world of frozen delights. Classic vanilla‚ rich chocolate‚ and strawberry are excellent starting points. However‚ don’t hesitate to venture into frozen yogurt variations or refreshing sorbet recipes.

Remember to prepare the mixture at least a day ahead. This crucial step allows complete cooling and volume increase‚ significantly improving the final texture. Pre-chilling is strongly recommended for optimal results‚ avoiding shortcuts in cooling time.

Avoiding Overflow: The Fill Line

Crucially‚ pay close attention to the fill line indicated on your Hamilton Beach ice cream maker’s canister. Exceeding this line is a common cause of messy overflows during the churning process. The mixture expands as it freezes‚ and exceeding the capacity prevents proper expansion within the canister.

Always ensure your ice cream base remains below the designated fill line before initiating the churning cycle. This simple precaution will save you cleanup and guarantee a smoother‚ more enjoyable ice cream-making experience.

Operating the Ice Cream Maker

Simply power on your Hamilton Beach ice cream maker to begin the churning process! Typically‚ churning takes around 20-30 minutes‚ but monitor for consistency. If it doesn’t stop‚ see troubleshooting.

Powering On and Churning Process

Once the canister is properly chilled and the ice cream mixture is poured in‚ securely attach the dasher and lid. Plug in your Hamilton Beach ice cream maker and power it on. The dasher will begin to rotate‚ churning the mixture.

Allow the unit to run continuously; do not attempt to open the lid during the churning process. The mixture will gradually thicken into ice cream. Observe the consistency – it should resemble soft-serve. The entire process usually takes between 20 and 30 minutes‚ depending on the recipe and ambient temperature.

Churning Time Guidelines

Generally‚ the churning process with a Hamilton Beach ice cream maker takes approximately 20 to 30 minutes. However‚ this is a guideline‚ and actual time can vary. Monitor the ice cream’s consistency; it’s ready when it resembles soft-serve.

If the unit doesn’t stop churning after 30 minutes‚ it likely indicates the mixture hasn’t fully frozen. Don’t worry‚ simply allow it to churn for a few more minutes‚ checking frequently. Avoid over-churning‚ as this can result in a grainy texture.

What to Do If the Unit Doesn’t Stop Churning

If your Hamilton Beach ice cream maker continues churning beyond 30 minutes‚ the mixture may not be fully frozen. First‚ unplug the unit. Check the canister – if ice is jammed‚ carefully remove it to allow continued churning.

Ensure the canister was adequately chilled for at least 24 hours. If the issue persists‚ the ice cream base might not have cooled sufficiently before churning. Allow it to chill longer before attempting again‚ and verify the fill line wasn’t exceeded.

Troubleshooting Common Issues

Common problems with your Hamilton Beach ice cream maker include jammed ice‚ salty taste‚ poor drainage‚ and overflow. Addressing these issues ensures delicious‚ homemade results!

Ice is Jammed

If your Hamilton Beach ice cream maker stops churning because the ice is jammed‚ immediately unplug the unit for safety. Carefully remove the dasher and lid‚ and inspect the canister for large ice chunks obstructing the dasher’s movement.

Ensure the canister is properly chilled – a warmer canister contributes to jamming. Avoid overfilling the canister beyond the designated fill line‚ as this can also cause ice to solidify and impede churning. Restart the machine after clearing the obstruction‚ and monitor closely.

Salty Tasting Ice Cream

A salty taste in your homemade ice cream from a Hamilton Beach maker usually indicates salt residue from the freezing process has contaminated the mixture. While these models don’t require salt‚ ensure no salt was accidentally introduced during canister preparation or cleaning.

Thoroughly wash all components‚ especially the canister and dasher‚ with fresh water before each use. Double-check that no salt remains in the freezer surrounding the canister. If the issue persists‚ try a different ice cream recipe to rule out ingredient interactions.

Poor Drainage

If you experience poor drainage with your Hamilton Beach ice cream maker‚ it often means the drain hole in the canister is partially blocked. Carefully inspect the hole for any frozen ice crystals or remnants of the ice cream mixture.

Gently clear the blockage with a soft object – avoid sharp tools that could damage the canister. Ensure the unit is completely thawed before attempting to clean the drain. Proper disassembly and washing of all components after each use will help prevent future drainage issues.

Lumpy Ice Cream

Lumpy ice cream from your Hamilton Beach maker often indicates insufficient churning or an improperly chilled canister. Ensure the canister is frozen solid for at least 24 hours‚ and allow it to sit at room temperature for approximately four minutes before assembly.

Verify the dasher is correctly attached and rotating freely during the churning process. A fully chilled base mixture‚ prepared at least a day in advance‚ also contributes to a smoother texture. Avoid overfilling beyond the fill line.

Ice Cream Overflowing the Canister

Ice cream overflowing the canister is a common issue with Hamilton Beach ice cream makers‚ easily prevented by adhering to the fill line. Strongly recommended is never exceeding this marked level during mixture preparation.

The mixture expands as it freezes‚ and exceeding the fill line guarantees spillage. Ensure the lid is securely locked in place to prevent leakage during churning. Pre-chilling the base for at least 24 hours also helps manage expansion‚ resulting in a cleaner churning process.

Cover Turns‚ Canister Doesn’t Turn

If the Hamilton Beach ice cream maker’s cover rotates‚ but the canister remains stationary‚ ice may be jammed within the unit. Immediately unplug the appliance and carefully disassemble it to inspect for obstructions.

Ensure the dasher is properly aligned and securely attached to the motor shaft. A frozen wall formation can also cause this issue; allowing the canister to warm slightly (around 4 minutes) before assembly can help. Verify the unit isn’t overloaded‚ as excessive mixture can strain the motor.

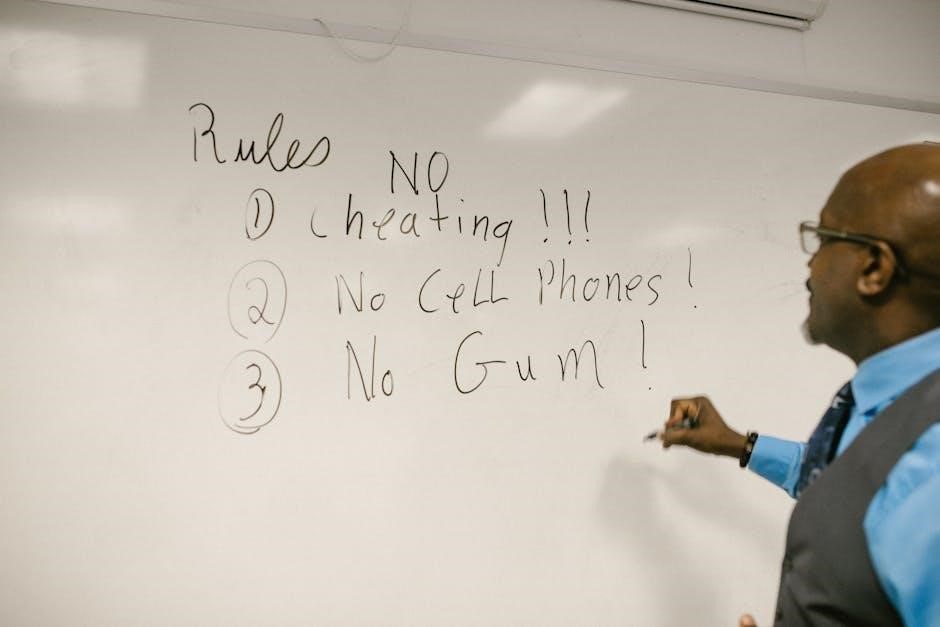

Safety Precautions

Hamilton Beach ice cream makers are not intended for use by children under 12 years of age. Always prioritize electrical safety by ensuring the appliance is unplugged before cleaning.

Age Restrictions (Not for Children Under 12)

Hamilton Beach strongly advises that this ice cream maker is not intended for use by children under the age of 12. Supervision is crucial when older children are operating the appliance‚ ensuring they understand and follow all safety instructions. The rotating parts and electrical components present potential hazards.

Carefully review the manual with any young operator before use. Emphasize the importance of not touching moving parts during operation and the need to unplug the unit before cleaning or disassembly. Prioritizing safety ensures a fun and enjoyable ice cream-making experience for everyone.

Electrical Safety

Hamilton Beach emphasizes several electrical safety precautions. Always ensure the appliance is properly grounded and used with a compatible electrical outlet. Never operate the ice cream maker with a damaged cord or plug‚ and avoid using extension cords if possible.

To prevent electrical shock‚ never immerse the motor base in water or other liquids. Always unplug the unit before cleaning‚ disassembling‚ or storing. If the appliance malfunctions or exhibits any signs of electrical issues‚ discontinue use immediately and contact customer support.

Cleaning and Maintenance

Hamilton Beach ice cream makers require disassembly for thorough cleaning. Wash components with warm‚ soapy water‚ ensuring proper drying before storage. Avoid abrasive cleaners to maintain the appliance’s quality.

Disassembling the Ice Cream Maker

Before cleaning your Hamilton Beach ice cream maker‚ complete disassembly is essential. First‚ unplug the unit and remove the lid. Carefully detach the dasher – it may require a gentle twisting motion. Next‚ lift the canister from the base. Ensure the canister is completely empty of any remaining ice cream.

Inspect all parts for any lingering residue. Remember to separate all components for individual washing. Proper disassembly ensures a thorough clean and prevents damage during the washing process‚ extending the life of your ice cream maker.

Washing the Components

After disassembly‚ wash all Hamilton Beach ice cream maker components with warm‚ soapy water. The canister‚ dasher‚ and lid are typically dishwasher safe (top rack recommended)‚ but hand washing is gentler. Avoid abrasive cleaners‚ as they can damage the surfaces.

Rinse thoroughly to remove all soap residue. Pay close attention to the dasher’s crevices. Ensure the canister is completely dry before reassembly. Never immerse the motor base in water; wipe it clean with a damp cloth only. Proper washing maintains hygiene and performance.

Proper Storage

To ensure longevity‚ store your Hamilton Beach ice cream maker components completely dry. The canister can be stored in the freezer for quick use‚ ready for your next batch. The dasher and lid should be stored in a cool‚ dry place‚ away from direct sunlight.

Avoid tightly packing components‚ which could cause damage. The motor base should be stored in a clean‚ dry location. Proper storage prevents mildew and ensures your ice cream maker remains in optimal condition for years of delicious creations.

Tips for Perfect Ice Cream

For optimal results‚ use high-quality ingredients and don’t hesitate to add mix-ins! Pre-chilling the base for at least 24 hours enhances flavor and texture.

Using High-Quality Ingredients

To truly elevate your homemade ice cream experience with your Hamilton Beach maker‚ prioritize ingredient quality. Rich‚ full-fat cream delivers a smoother‚ creamier texture compared to lower-fat alternatives. Real vanilla extract provides a superior flavor profile over imitation versions.

Fresh‚ ripe fruits contribute vibrant tastes‚ while high-quality chocolate enhances decadent recipes. Remember‚ the final product’s flavor is directly linked to the ingredients you begin with‚ so invest in the best for a truly exceptional homemade treat!

Adding Mix-Ins

When incorporating mix-ins into your Hamilton Beach ice cream‚ timing is key! Add them during the last few minutes of the churning process‚ typically after the mixture has thickened considerably. This prevents them from sinking to the bottom or becoming overly crushed.

Consider chopped nuts‚ chocolate chips‚ fruit pieces‚ or cookie crumbles. Ensure mix-ins are appropriately sized – smaller pieces distribute more evenly. Don’t overfill; a generous‚ but not excessive‚ amount will yield the best results for a delightful texture and flavor!

Exploring Different Recipes

Beyond traditional ice cream‚ your Hamilton Beach maker excels at frozen yogurt and refreshing sorbets! Experiment with diverse flavors and ingredients for exciting homemade desserts.

Frozen Yogurt Variations

Hamilton Beach ice cream makers aren’t limited to just ice cream; they’re fantastic for creating creamy‚ tangy frozen yogurt! Start with a base of yogurt – Greek yogurt yields a thicker consistency. Add fruit purees like strawberry or mango‚ or swirl in fruit pieces after churning.

For a richer flavor‚ incorporate a touch of honey or maple syrup. Remember to pre-chill the yogurt base thoroughly for optimal results. Experiment with different yogurt types and mix-ins to discover your perfect frozen yogurt creation!

Sorbet Recipes

Hamilton Beach ice cream makers excel at crafting refreshing sorbets! Begin with a simple syrup base – equal parts sugar and water‚ heated until dissolved‚ then cooled. Blend this with your chosen fruit puree‚ such as raspberry‚ lemon‚ or peach.

For a vibrant flavor‚ use ripe‚ seasonal fruits. Ensure the mixture is well-chilled before churning in your ice cream maker. Sorbet tends to be softer than ice cream‚ so enjoy it immediately or store it briefly in the freezer. Experiment with herbs like mint for unique twists!

Where to Find More Information

Hamilton Beach’s official website provides manuals and support for your ice cream maker. Online resources‚ including user forums‚ offer additional tips and troubleshooting guidance.

Hamilton Beach Official Website

Hamilton Beach’s official website is the primary resource for comprehensive information regarding your ice cream maker. You can directly access downloadable manuals for specific models like the 68320 or 68880‚ providing detailed instructions and safety precautions.

The website also features a robust support section‚ often including FAQs addressing common issues such as churning problems‚ salty-tasting ice cream‚ or canister freezing. Furthermore‚ you may find helpful videos demonstrating assembly and operation‚ ensuring a smooth and enjoyable ice cream-making experience. Explore their site for the latest updates and assistance!

Online Manuals and Support

Beyond the Hamilton Beach official website‚ numerous online resources offer support for your ice cream maker. Many websites host downloadable manuals‚ providing troubleshooting guides for issues like jammed ice or overflowing canisters.

User forums and communities dedicated to kitchen appliances often contain valuable tips and solutions shared by fellow owners experiencing similar challenges. Searching online for your specific model number (e.g.‚ 68330) alongside keywords like “troubleshooting” or “instructions” will yield relevant results‚ enhancing your ice cream-making journey.