Welcome! This manual unlocks masterful control of your Prodigy P2, exploring new possibilities for creativity and innovation in trailer braking systems.

Before utilizing your wiring diagram, understand its potential; this guide empowers precision functionality, ensuring safe and reliable towing experiences for all journeys.

TheProdigy.ru provides complete and accurate information about the legendary British band, The Prodigy, alongside fresh news and downloadable audio files.

What is a Brake Controller?

A brake controller is a vital component in any towing setup, acting as the intermediary between your tow vehicle’s braking system and the brakes on your trailer. It allows the driver to proportionally apply the trailer’s brakes, ensuring synchronized and safe stopping power. Without a brake controller, the trailer’s momentum can quickly overwhelm the tow vehicle, leading to dangerous situations like jackknifing or loss of control.

Essentially, it translates the braking signal from your vehicle into an electrical signal that activates the trailer brakes. Modern controllers, like the Prodigy P2, offer features like proportional braking, manual override, and slide control, enhancing safety and convenience. Understanding its function is crucial for responsible towing. The Prodigy P2 wiring diagram is key to unlocking its potential.

Exploring possibilities with your new controller means understanding its role in maintaining stability and control during towing. Resources like TheProdigy.ru offer valuable information about related technologies and safety practices.

The Prodigy P2: An Overview

The Prodigy P2 is a widely respected and highly capable brake controller known for its smooth, proportional braking and user-friendly interface. It’s designed to work with most electric and electric-over-hydraulic trailer brake systems, offering reliable performance for a variety of towing needs. This controller features a digital display that provides real-time feedback on brake output and system status.

Key features include adjustable sensitivity settings, manual brake override, and a slide control for precise brake application. The P2’s proportional braking system automatically adjusts the trailer’s braking force based on the tow vehicle’s deceleration, providing a natural and responsive feel. Mastering its functionalities unlocks a safer towing experience.

Resources like wiring diagrams are essential for proper installation. Websites like TheProdigy.ru offer community support and information related to towing technology and safety.

Installation of the Prodigy P2

Proper installation is crucial for optimal performance! Carefully follow the wiring diagram basics, ensuring secure connections to both the vehicle and trailer brake systems.

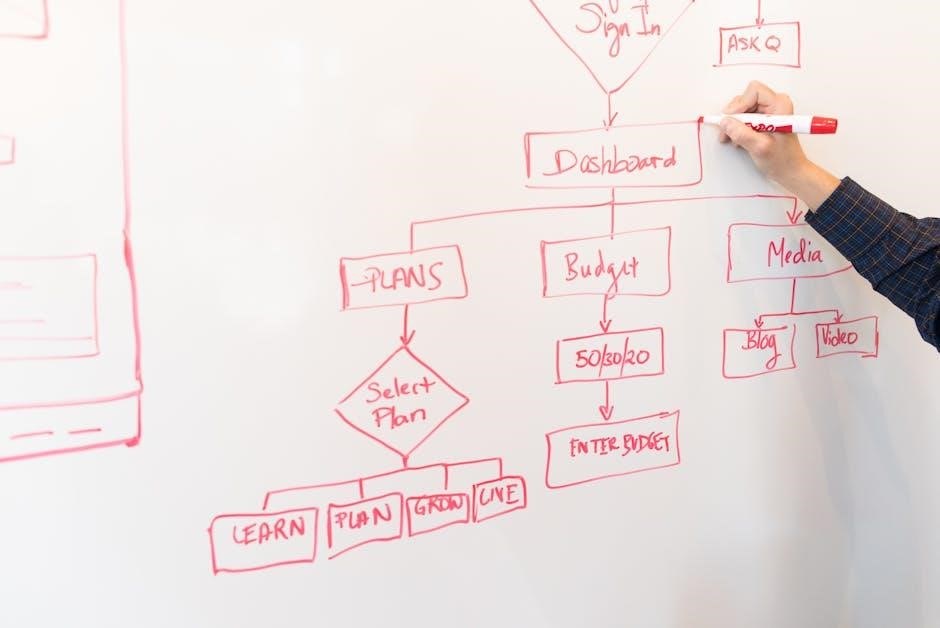

Wiring Diagram Basics

Understanding the wiring diagram is the foundation of a successful Prodigy P2 installation. The diagram details each wire’s function, color-coding, and connection points within your vehicle and trailer. Key components include the brake circuit, ground connection, power source, and signal wire.

Carefully identify the vehicle’s brake light circuit – typically a four or five-wire flat connector, or a seven-way RV blade connector. The Prodigy P2 requires a dedicated 12-volt power source, often found in the vehicle’s fuse box. Ensure a solid ground connection to the vehicle’s chassis for reliable operation.

Refer to the specific diagram included with your controller, as wiring configurations can vary based on vehicle and trailer types. Double-check all connections before applying power, and use appropriate connectors and crimping tools for secure, long-lasting results. Incorrect wiring can lead to controller malfunction or damage to your vehicle’s electrical system.

Connecting to the Vehicle

Begin by locating the vehicle’s wiring harness compatible with trailer brakes, typically behind the dashboard or in the engine compartment. Carefully disconnect the existing connector, if present, and identify the corresponding wires – brake light, ground, and 12-volt power.

Utilize the provided wiring adapter (if applicable) to connect the Prodigy P2’s wiring harness to the vehicle’s harness. If splicing is necessary, use proper crimping tools and heat-shrink tubing to ensure secure and insulated connections. Securely mount the controller head in a readily accessible location, avoiding interference with driving controls.

Connect the ground wire to a clean, unpainted metal surface on the vehicle’s chassis. Verify the 12-volt power connection with a multimeter to ensure proper voltage. Test the brake light signal by activating the vehicle’s brakes – the controller should display activity. Double-check all connections before proceeding to trailer connection.

Connecting to the Trailer

Locate the trailer’s wiring connector, typically a 7-pin or 4-pin RV blade style. Ensure the connector is clean and free of corrosion. Match the wires from the trailer to the corresponding wires from the Prodigy P2’s connector – brake input, ground, and running lights.

Connect the brake wire from the trailer to the brake output wire from the controller. Securely connect the ground wire to the trailer’s frame, ensuring a solid electrical connection. Verify the running light connection to power the trailer’s lights.

Test the trailer brakes by manually activating the controller and observing the trailer’s brake lights. Confirm proper operation before driving. Inspect all connections for tightness and security. Remember to consult your trailer’s manual for specific wiring diagrams and recommendations.

Understanding the Prodigy P2 Interface

Explore the control head display for intuitive adjustments! Master settings to fine-tune proportional braking, ensuring optimal performance and safety during every towing experience.

The Control Head Display

The Prodigy P2’s control head display is designed for clear and concise information delivery, providing the user with essential braking system status at a glance. The display utilizes a series of LED indicators and a digital readout to communicate vital data. Understanding these elements is crucial for effective operation.

Power Indicator: A solid green light confirms the controller is receiving power. If the light is off, check your vehicle’s fuse box and wiring connections. Proportional Gain Indicator: This series of LEDs displays the currently selected proportional gain setting, ranging from minimal to maximum. Adjusting this setting controls the responsiveness of the brakes to your vehicle’s deceleration.

Manual Override Indicator: When activated, this light illuminates, indicating the manual brake control is engaged. Error Code Display: In the event of a system malfunction, the display will show a specific error code, which can be referenced in the troubleshooting section of this manual. Trailer Disconnected Indicator: This light alerts you if the trailer connection is lost or faulty. Regularly checking the display ensures optimal braking performance and safe towing.

Adjusting the Controller Settings

The Prodigy P2 offers adjustable settings to fine-tune braking performance to your specific vehicle and trailer combination. The primary adjustment is the Proportional Gain, controlled via the rotary dial on the control head. Start with a low setting and gradually increase it while driving in a safe, open area.

Higher gain settings result in more aggressive braking, while lower settings provide a smoother, more gradual response. Observe your trailer’s behavior – excessive braking or trailer sway indicates the gain is too high. Manual Override is adjusted using the slider control, allowing independent brake application. This is useful for testing or emergency situations.

Sensitivity Adjustment: Some models feature a sensitivity adjustment, influencing how quickly the controller responds to initial braking. Refer to the detailed wiring diagram for specific model features. Proper adjustment ensures synchronized braking, maximizing safety and control during towing. Remember to consult the troubleshooting section if issues arise.

Proportional Braking Explained

Proportional braking is the core function of the Prodigy P2, mirroring your vehicle’s braking intensity. As you apply the brakes, the controller sends a corresponding signal to the trailer brakes, ensuring synchronized deceleration. This system vastly improves safety and control compared to traditional time-delayed braking.

The Prodigy P2 utilizes an internal accelerometer to detect deceleration rates. This data is then used to calculate the appropriate braking force for the trailer. Adjusting the proportional gain (via the rotary dial) modifies the sensitivity of this system. A higher gain means more aggressive trailer braking for a given vehicle deceleration.

Properly calibrated proportional braking minimizes trailer sway and provides a more natural towing experience. It’s crucial to test and adjust the settings based on your specific vehicle, trailer, and load. The goal is smooth, controlled stops without excessive trailer braking or “pushing” from the trailer’s weight.

Using the Prodigy P2 Features

Explore manual, proportional, and slide control functionalities for optimal trailer braking. Masterful control empowers precision, ensuring safe and reliable towing experiences on every journey!

Manual Mode Operation

Engaging Manual Mode: The Prodigy P2’s manual mode provides direct, driver-controlled braking force, bypassing the proportional circuitry. This is particularly useful in situations demanding immediate and consistent braking, such as steep descents or navigating challenging terrain. To activate manual mode, locate the mode switch on the control head and position it to ‘Manual’.

Applying Brakes: Once in manual mode, the braking force is directly correlated to the pressure applied to the manual brake lever. A gentle press results in a light braking application, while a firmer, more forceful press delivers stronger braking. Practice in a safe, open area to familiarize yourself with the responsiveness of the system.

Monitoring Performance: Continuously monitor the trailer’s braking response and adjust the lever pressure accordingly. Avoid abrupt or jerky movements, as this can cause instability. Remember, in manual mode, you are solely responsible for controlling the trailer’s braking – consistent attention is crucial for safe towing. The control head display will indicate the applied braking percentage, allowing for precise adjustments.

Proportional Mode Operation

Understanding Proportional Braking: The Prodigy P2’s proportional mode is its defining feature, automatically adjusting trailer braking force based on the vehicle’s deceleration. This mimics the braking behavior of a self-contained trailer, enhancing stability and control. To activate, set the mode switch on the control head to ‘Proportional’.

How it Works: When you apply the vehicle’s brakes, the P2 senses the deceleration rate and proportionally applies the trailer brakes. The harder you brake, the harder the trailer brakes – and vice versa. This synchronized braking action minimizes trailer sway and provides a more natural towing experience.

Initial Setup & Adjustment: Proper adjustment of the gain setting is vital for optimal performance. Start with a low gain and gradually increase it until the trailer brakes smoothly and in sync with the tow vehicle. Monitor the trailer’s response during test braking to fine-tune the settings. Consistent monitoring ensures safe and effective proportional braking.

Slide Control Functionality

What is Slide Control? The Prodigy P2 features a unique ‘Slide Control’ function designed to mitigate trailer sway, particularly useful when towing in challenging conditions or with heavier loads. This feature actively monitors for potential sway and subtly adjusts braking to counteract it, promoting stability.

Activating Slide Control: To engage Slide Control, press and hold the dedicated button on the control head. A visual indicator will confirm activation. The system operates automatically once engaged, requiring no further input during normal towing.

How it Works: When sway is detected, Slide Control selectively applies the trailer brakes on the opposite side of the sway, gently correcting the trailer’s trajectory. This prevents the sway from escalating and helps maintain a straight towing path. Remember to disengage Slide Control when not needed for standard proportional braking.

Troubleshooting Common Issues

Facing problems? This section guides you through resolving typical issues like power failures, brake activation problems, and deciphering error codes for a smooth journey.

Explore possibilities with your Prodigy P2, ensuring safe and reliable towing experiences, referencing the manual for detailed solutions and support.

No Power to the Controller

Problem: If your Prodigy P2 brake controller displays no power, begin by verifying the connection at the vehicle’s battery. Ensure the positive wire is securely fastened and not corroded. A loose or corroded connection is a frequent cause of power loss.

Check the Fuse: Locate the inline fuse on the controller’s power wire – typically found close to the battery connection. Inspect the fuse for any signs of damage or breakage. Replace it with a fuse of the exact same amperage rating if necessary. Using a higher amperage fuse can cause serious damage.

Wiring Inspection: Carefully examine the entire length of the power wire for any cuts, crimps, or exposed wiring. Damage to the wire can interrupt the power supply. Repair or replace any damaged sections.

Ground Connection: Confirm a solid ground connection. The controller requires a good ground to function correctly. Ensure the ground wire is securely attached to a clean, unpainted metal surface on the vehicle’s chassis.

Test with Voltmeter: Use a voltmeter to test for voltage at the controller’s power input. If no voltage is present, the issue lies upstream, likely in the vehicle’s wiring or fuse box.

Brakes Not Activating

Initial Check: If the trailer brakes aren’t activating despite the controller showing power, first verify the emergency breakaway cable is disconnected. An engaged breakaway cable overrides the controller.

Trailer Wiring: Inspect the trailer’s wiring harness for damage or corrosion. A faulty ground at the trailer is a common culprit. Ensure the trailer’s brake lights illuminate when the vehicle’s brakes are applied – this confirms basic trailer wiring functionality.

Controller Settings: Double-check the controller’s settings. Confirm the controller is set to ‘Proportional’ or ‘Manual’ mode, depending on your preference and towing conditions. Adjust the sensitivity and maximum brake pressure settings.

Actuator Function: Verify the trailer’s brake actuator is functioning correctly. Manually apply the brakes at the actuator to confirm mechanical operation. A faulty actuator will prevent brake activation.

Signal Verification: Use a test light to confirm the controller is sending a signal to the trailer brakes when the vehicle brakes are applied. No signal indicates a problem with the controller or its wiring to the trailer.

Error Codes and Their Meanings

Error Code 1 (Short to Ground): Indicates a short circuit to ground in the trailer wiring. Disconnect the trailer and inspect wiring for damaged insulation. Repair or replace damaged wires.

Error Code 2 (Open Circuit): Signals an open circuit, meaning a broken wire or loose connection between the controller and the trailer. Check all connections at the vehicle and trailer ends.

Error Code 3 (Low Voltage): Displays when the vehicle’s charging system voltage is too low to operate the controller effectively. Verify the vehicle’s battery is fully charged and the alternator is functioning.

Error Code 4 (High Voltage): Indicates excessive voltage from the vehicle’s charging system. This could damage the controller; investigate the vehicle’s charging system immediately.

Error Code 5 (Communication Error): Suggests a problem with communication between the controller and the trailer’s brake system. Recheck all wiring connections and ensure compatibility.

Maintenance and Care

Preserve Performance! Regularly clean the controller and meticulously check wiring connections for optimal functionality and longevity. Firmware updates, if available, enhance performance.

TheProdigy.ru offers comprehensive information about The Prodigy, including news, audio downloads, and a dedicated fan forum for discussions.

Cleaning the Controller

Maintaining a clean Prodigy P2 is crucial for optimal performance and longevity. Dust, dirt, and grime can accumulate on the control head and within the wiring connections, potentially causing malfunctions or inaccurate readings.

To clean the exterior, use a soft, dry cloth. Avoid abrasive cleaners or solvents, as these can damage the plastic casing and electronic components. For stubborn dirt, lightly dampen the cloth with water, ensuring it is wrung out thoroughly to prevent moisture from entering the unit.

Pay particular attention to the display screen and button surfaces. Gently wipe these areas to remove fingerprints and smudges. Inspect the wiring connections periodically for corrosion or debris. If corrosion is present, carefully clean the terminals with a wire brush or electrical contact cleaner.

Remember to disconnect the power supply before cleaning any electrical components. Regular cleaning, combined with periodic inspections, will help ensure your Prodigy P2 continues to operate reliably for years to come. TheProdigy;ru provides a community for fans to share information.

Checking Wiring Connections

Regularly inspecting your Prodigy P2’s wiring connections is paramount for safe and reliable trailer braking. Loose or corroded connections can lead to intermittent brake function or complete failure, posing a significant safety risk.

Begin by visually examining all connections – at the control head, the vehicle’s wiring harness, and the trailer connector. Look for signs of corrosion, fraying, or loose wires. Gently tug on each wire to ensure it’s securely fastened. If a connection feels loose, tighten it appropriately.

Use a wire brush or electrical contact cleaner to remove any corrosion from the terminals. Apply dielectric grease to the connections after cleaning to prevent future corrosion. Ensure the ground wire is securely attached to a clean, unpainted metal surface on the vehicle’s frame.

A faulty ground is a common cause of brake controller issues. Remember to disconnect the power before inspecting wiring. TheProdigy.ru is a dedicated website for The Prodigy fans.

Firmware Updates (If Applicable)

Determining if your Prodigy P2 requires a firmware update is crucial for optimal performance and access to the latest features. Check the manufacturer’s website, (hypothetical link), for available updates and instructions. Firmware updates can address bugs, improve compatibility with newer vehicles and trailers, and enhance overall braking control.

The update process typically involves downloading the firmware file to a compatible USB drive and connecting it to the controller. Follow the on-screen prompts carefully, ensuring the controller has a stable power supply throughout the update; Do not interrupt the update process, as this could damage the controller.

If an update fails, consult the manufacturer’s troubleshooting guide or contact their customer support for assistance. Regularly checking for updates ensures your Prodigy P2 operates at its peak efficiency. TheProdigy.ru offers comprehensive information about The Prodigy.

Remember to back up any custom settings before initiating a firmware update.